Strapping Machines

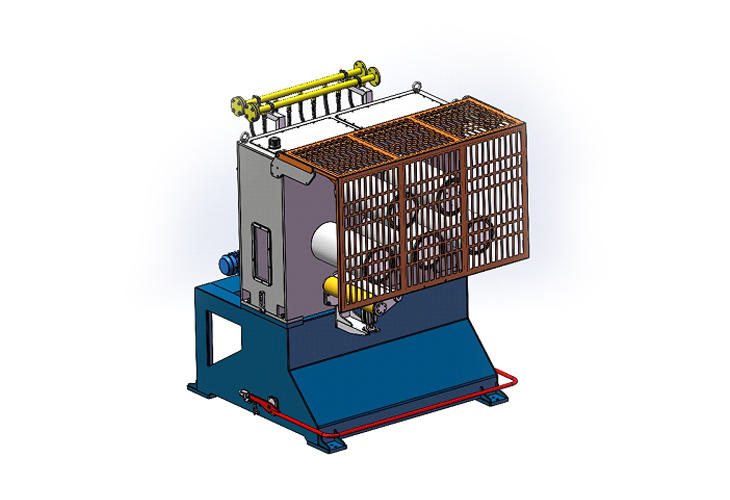

Automatic level-seal strapping machine with top presser

Description

-can be integrated into most conveyor lines

-friction and welding system

-high sealing tension due to a minimum distance from package to sealing unit

-programmable control with panel inclusive manual control with functional sequence of strapping control

-potential-free contacts to upstream and downstream equipment

-plastic strap guidance- low wear, controlled strap path

-automatic strap loop ejection when machine cycles without bundle

-stroke of strap guide frame via belt drive

-automatic strap threading

-strap end detection with ejection of remaining strap

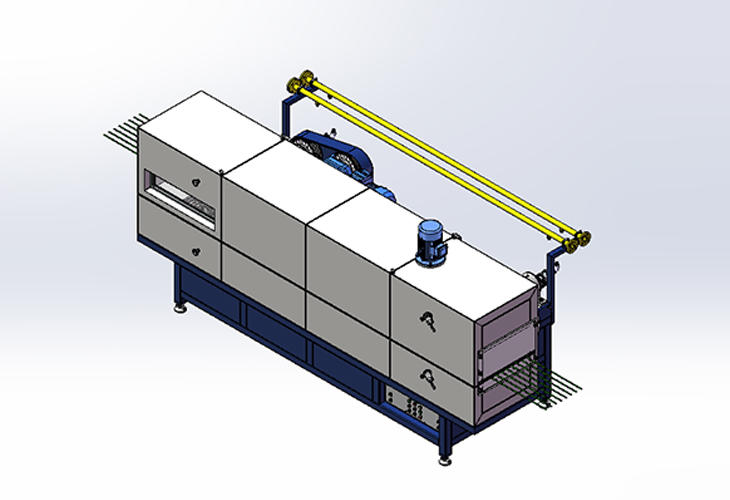

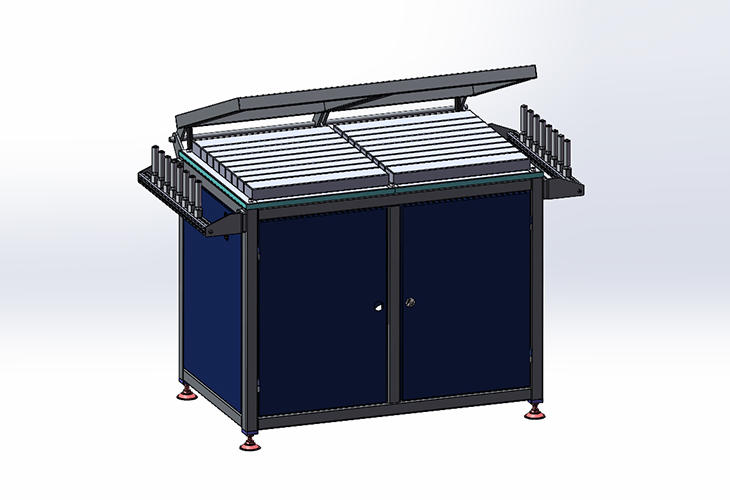

Automatic side-seal strapping machine with flap frame

Description

- Best strapping machines are series-produced based on a modular principal

- Sturdy design

-can be integrated into most conveyor lines

-friction and welding system

-automatic strap threading system

-robust single-column steel construction

-fully electrically-driven

-side-mounted sealing head

-easy accessibility and tool-free disassembly of strap path components

-dispenser variably mountable

-PLC siemens

Wrapping machines

BEST wrapping solution are designed and manufactured for a long and undisturbed life. Both durable and reliable, our solution have been built to endure all working conditions and made for packaging any product in mind at the most competitive price.

-Turntable wrapping machine

-Arm wrapping machines

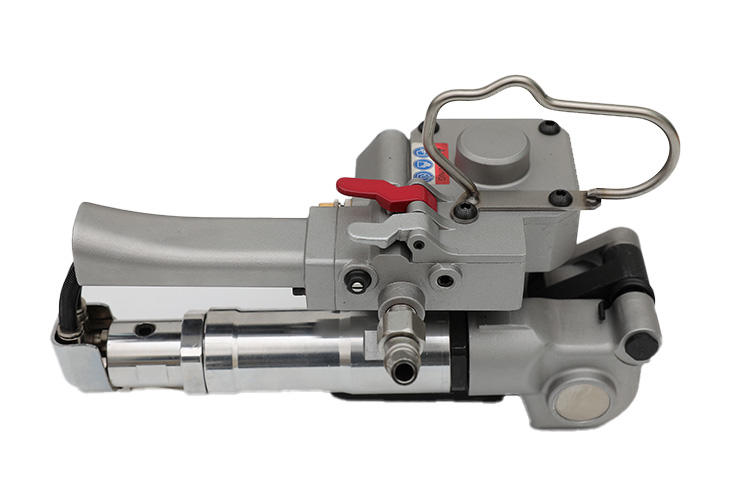

strapping tool

Best packing supplies plastic, battery, pneumatic and manual strapping tools.

Strapping materials

Whatever industry sector you operate in, whether in Baling, Building Supplies, Canning or Bottling, Printing, Wood and Timber, Metals, Corrugated Board, or Logistics, we have the right strapping solution for you.

We are also very flexible in terms of deliveries of our strapping. From a single box to an entire truck or container load, everything is possible by arrangement. If you are interested, we support you individually, determine your needs and also supply larger quantities rapidly.

The right strapping for the right purpose

PP strapping

We manufacture PP straps as standard in widths 5-18 millimeters in white or black. On request, we will be happy to produce it for you in other colors as well. PP strapping material is particularly suitable for strapping packages, cartons or other containers, as well as lighter pallets.

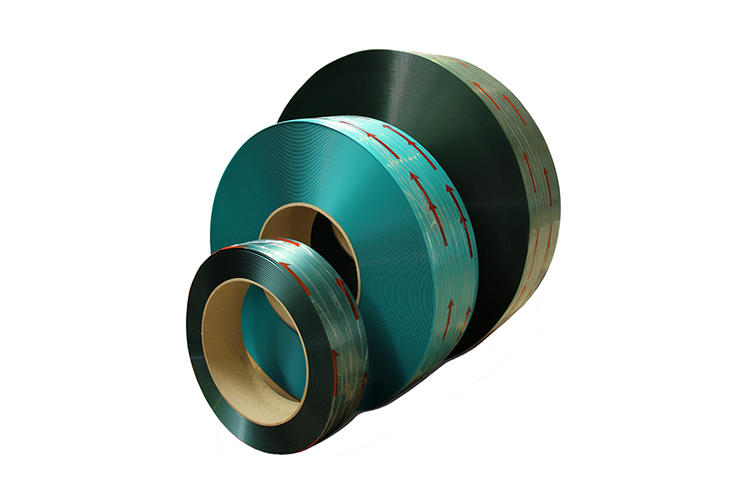

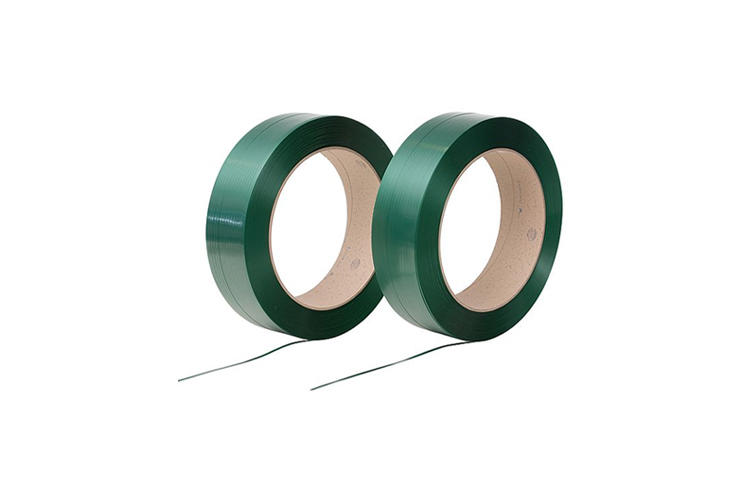

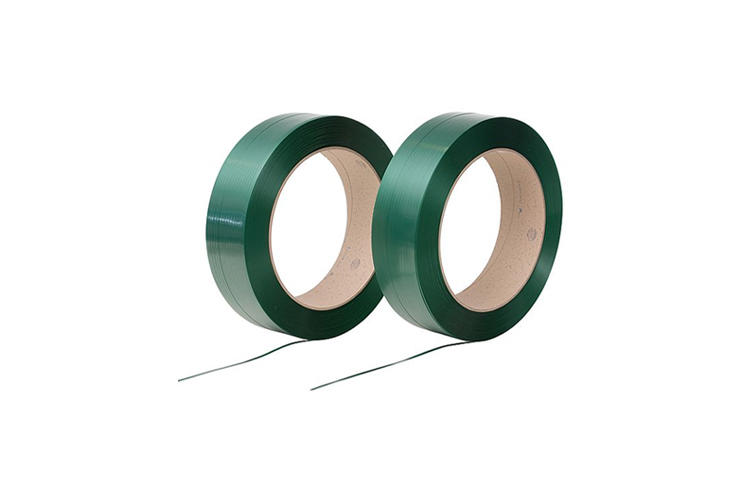

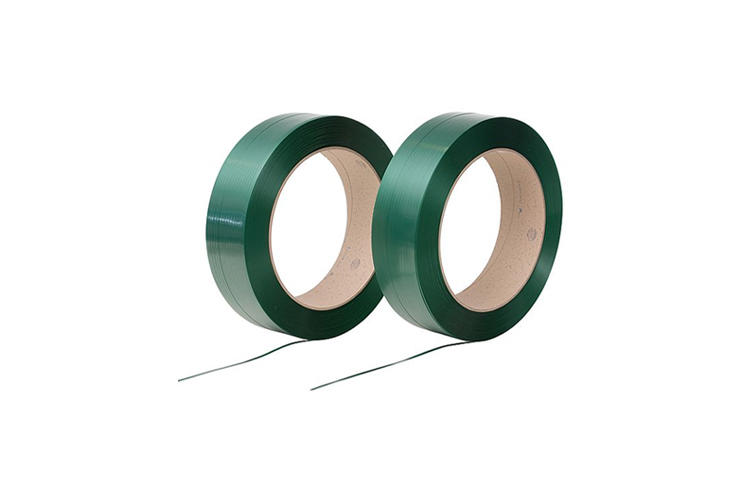

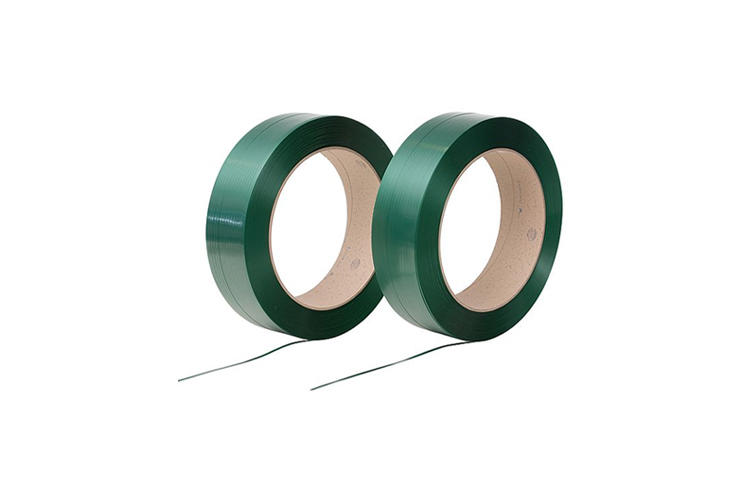

PET straps

Our PET strapping consists of one hundred percent recycled plastic bottles (bottle flakes) and is equally suitable for friction or ultrasonic welding. After use, it can be easily fed back into the material cycle. Our PET strapping is available in width 9.5 to 32 millimeters. It is thermally stable and, depending on width, can sustain loads of between 180 and 1250kg.

Depending on protective requirements for transport of goods there are three product groups

BESTstrap™ ECO

Lightweight and resource-saving strap,which meets requirements for full protection and holding strength of transported goods. BESTstrap™ ECO is available in the range of 9.5-19mm width and 0.6 -1.27 mm thickness. It can be used for a wide range of application: strapping paper, cardboard, cans, plastic products, packages of different timber and wood products.

BESTstrap™ Plus

This type of strap is particularly suited for complete automatic strapping applications. It’s applicable in high-speed strapping process. BESTstrap™ plus is available in a range of 9 -32mm width and 0.5 -1.27mm thickness and is obtainable with embossed and smooth surface.

BESTstrap™ Ultra

It’s a high performance strap for special requirements regarding tensile strength and seal seal efficiency. It can replace high-strength steel strap in heavy applications, especially in the metal industry and cotton industry. BESTstrap™ Ultra is available in the range 19 x1.27 to 32 x 1.27

BESTstrap™

is available as normal coil (20kg), jumbo coil (75kg), and suitable for all types of dispensers.

-

-

PET STRAP - 9.5 MM

Thickness 0.54 mm - Core - 406 mm -

PET STRAP - 9.5 MM

Thickness 0.64 mm - Core 406 mm -

PET STRAP - 12.0 MM

Thickness 0.54 mm - Core 406 mm -

PET STRAP - 12.0 MM

Thickness 0.58 mm - Core 406 mm -

PET STRAP - 12.0 MM

Thickness 0.62 mm - Core 406 mm -

PET STRAP - 12.0 MM

Thickness 0.70 mm - Core 406 mm -

PET STRAP - 12.5 MM

Thickness 0.54 mm - Core 406 mm -

PET STRAP - 12.5 MM

Thickness 0.58 mm - Core 406 mm -

PET STRAP - 12.5MM

Thickness 0.66 mm - Core 406 mm -

PET STRAP - 15.0 MM

Thickness 0.55 mm - Core 406 mm -

PET STRAP - 15.0 MM

Thickness 0.66 mm - Core 406 mm -

PET STRAP - 15.0 MM

Thickness 0.80 mm - Core 406 mm -

PET STRAP - 15.5 MM

Thickness 0.89 mm - Core 406 mm

PP straps

We manufacture PP straps as standard in widths 5-18 millimeters in white or black. On request, we will be happy to produce it for you in other colors as well. PP strapping material is particularly suitable for strapping packages, cartons or other containers, as well as lighter pallets.

-

PP STRAP - 5.0 MM

Thickness 0.35 mm - Core 200 mm -

PP STRAP - 5.0 MM

Thickness 0.40 mm - Core 200 mm -

PP STRAP - 5.0 MM

Thickness 0.47 mm - Core 150 mm -

PP STRAP - 5.0 MM

Thickness 0.47 mm - Core 200 mm -

PP STRAP - 6.0 MM

Thickness 0.55 mm - Core 200 mm -

PP STRAP - 8.0 MM

Thickness 0.45 mm - Core 200 mm -

PP STRAP - 9.0 MM

Thickness 0.55 mm - Core 200 mm -

PP STRAP- 10.0 MM

Thickness - 0.55 mm - Core 200 mm -

PP STRAP - 12.0 MM

Thickness 0.45 mm - Core 200 mm -

PP STRAP - 12.0 MM

Thickness 0.55 mm - Core 200 mm -

PP STRAP - 12.0 MM

Thickness 0.55 - Core 406 mm -

PP STRAP - 10.0 MM

Thickness - 0.55 mm - Core 200 mm -

PP STRAP- 12.0 MM

Thickness 0.63 mm - Core 280 mm -

PP STRAP - 12.0 MM

Thickness 0.63 mm - Core 406 mm -

PP STRAP - 12.0 MM

Thickness 0.80 mm - Core 200 mm -

PP STRAP - 12.0 MM

Thickness 0.80 mm - Core 280 mm -

PP STRAP - 12.0 MM

Thickness 0.80 mm - Core 406 mm -

PP STRAP - 15.0 MM

Thickness 0.90 mm - Core 406 mm

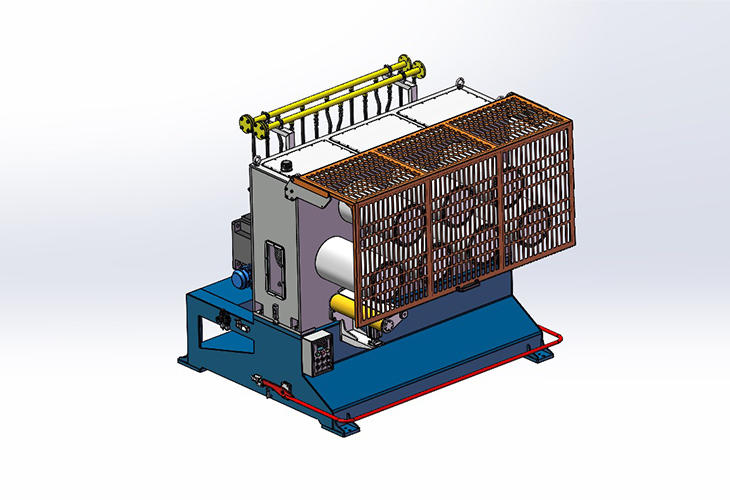

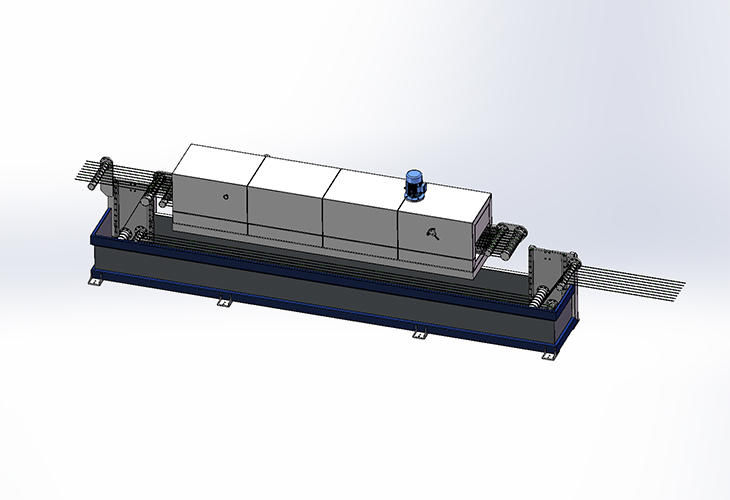

Extrusion line for strapping tapes

Best solution for PET/PP strapping tape producer based on reliability of the extrusion process guarantying the highest efficiency level in terms of production capacity and quality of the final product.

Main features

→BSET Extrusion, spinning, stretching and winding devices/process is suitable for both PET(100% bottle flakes) and PP plastic strap each tape with dedicated parameters and accessories set to suit best performance both in automatic and manual strapping packaging machine.

→BEST winding system for parallel winding of plastic strap in line with extrusion, can take up strap from 4 up to 32mm width. we only serve automatic version which has a modular and compact design for permanent automatic operation in line with extrusion. One the preselected of package is reached is wrapped by an automatic foil unwinding group. The full bobbin is automatically doffed and a new tube is positioned on the mandrel for new package winding.

→Extrusion line guaranties the highest efficiency level in term of production capacity and quality of the final product both for PP and PET strap with several models lines, each one has own design with capacity from 1200 tons/year up to more than 7000 tons/year

→All lines are capable to produce all strap size from 5 to 32mm respecting the most restricted standard of quality for dimension, weight, breaking load, elongation.

→BEST STRAP extrusion line is designed, assembled and tested in house to meet customer expectation and trust.

line configuaration for strapping tapes

The raw material PET respectively PP is melted in an extrusion procedure and then pressed through a tool forming the primary shape. After water cooling in a quenching tank the melted mass is stretched, relaxed, cooled once again and finally spooled onto coils as finished strap.

Raw materials: PET virgin pellets

PET bottle flakes

Output: 300 kg/h – 4 tapes

600 kg/h – 6 tapes

850 kg/h – 8 tapes

1000 kg/h – 10 tapes

Production speed: up to 210 m/min – manual winders

with 2 winding positions

up to 300m/min – automatic winding system

working width: 400 mm – 4 tapes

600 mm – 6, 8 and 10 tapes

800 mm – 10 tapes

winders Best WT systems

Screw design:

Extruder sizes:

(dryer needed) 100 mm – 300 kg/h

120 mm – 600 kg/h

130 mm – 850 kg/h

150 mm – 1000 kg/h

Output depending on resin

Special developments / other line configurations possible!

PET/PP combination line possible

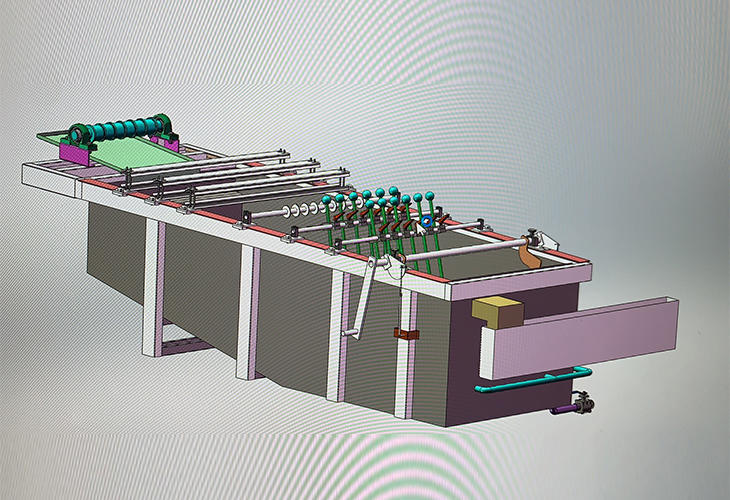

Main components for the prodcution of strapping tapes

-

Draw stand with 7 roller

-

Draw stand with 5 rollers

-

Hot air stretching oven

-

Hot air relaxing oven integrate with water cooling tank

-

Quench tank

-

Strapping winder automatic/manual

-

Water removal unit

Gear Box

Relaxing Oven

Candle Filter

The filtration process involves passing the liquid or gas through the porous material, which traps the solid particles while allowing the clean fluid or gas to pass through. Over time, as the particles accumulate on the surface of the filter, the flow rate may decrease, and the filter requires cleaning or replacement.

Candle filters are used in diverse applications, including:

Water treatment: Candle filters can be employed in water treatment plants to remove impurities and contaminants from drinking water or wastewater.

Oil filtration: In industries such as automotive, manufacturing, and aerospace, candle filters can be used to clean and purify various oils, such as engine oil, hydraulic oil, or lubricating oil.

Chemical processing: Candle filters are utilized in chemical processing to separate solid particles from liquids in various chemical reactions.

Gas filtration: In some cases, candle filters can be adapted for gas filtration applications, where they remove particulates or impurities from gas streams.

Quench Tank

Metallurgy: In metallurgical processes, quench tanks are used to cool metal alloys rapidly after they have been heated to high temperatures during processes like heat treatment or annealing. The rapid cooling prevents the formation of undesirable crystal structures and enhances the material's hardness and strength.

Heat treatment: Quench tanks are an essential part of heat treatment processes, such as hardening, tempering, and annealing of steel and other metals. They play a crucial role in achieving the desired mechanical properties of the material.

Forging and casting: After forging or casting metal components, they are often placed in a quench tank to prevent further heat-related changes and to stabilize the material.

Welding: Some welding processes, especially in the case of certain metals, require post-weld quenching to relieve stresses and enhance the weld's properties.

The choice of quenching medium (water, oil, or polymer) depends on the material being processed and the desired outcome. Water quenching provides the most rapid cooling but may lead to higher levels of distortion or risk of cracking. Oil and polymer solutions offer more controlled cooling rates and can be suitable for certain materials or specific applications.