PET (Polyethylene Terephthalate) strapping tape is naturally resistant to weathering, moisture, and UV radiation due to its molecular structure and inherent properties.

Chemical Structure: PET is a type of thermoplastic polymer composed of repeating units of ethylene glycol and terephthalic acid. This chemical structure imparts inherent resistance to moisture and water absorption. Unlike materials like paper or some natural fibers, PET does not readily absorb water or moisture, which helps prevent degradation and weakening of the material.

Hydrophobic Nature: PET is hydrophobic, meaning it repels water and resists wetting. This hydrophobicity contributes to its resistance to moisture and weathering. Moisture is less likely to be absorbed into the material, reducing the risk of water-induced damage such as swelling, warping, or weakening.

UV Stabilizers: Many PET strapping tapes are formulated with UV stabilizers or inhibitors during the manufacturing process. UV stabilizers help protect the material from the damaging effects of ultraviolet (UV) radiation from the sun. UV radiation can degrade polymers over time, leading to color fading, embrittlement, and reduced strength. UV stabilizers act as a shield, absorbing and dissipating UV energy, thus extending the lifespan of the material.

Additives and Surface Treatments:

PET strapping tape can be further enhanced with additives and surface treatments that improve its resistance to weathering. These additives can include antioxidants, anti-aging agents, and coatings that provide an additional layer of protection against environmental factors.

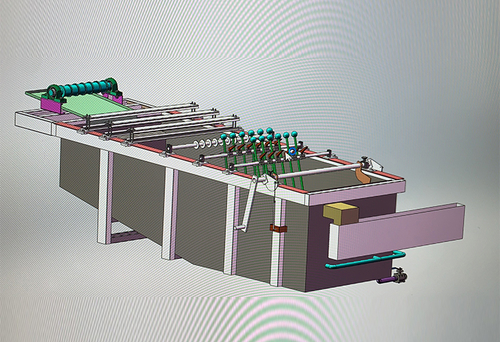

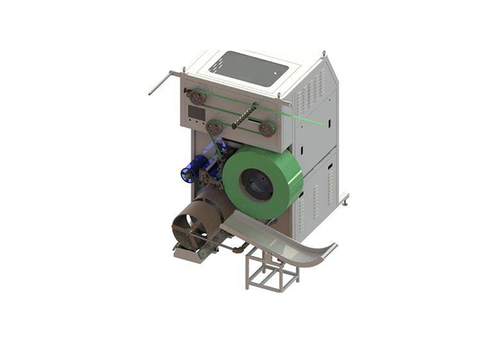

Manufacturing Process: The extrusion and heat setting processes used to manufacture PET strapping tape contribute to its resistance to weathering. The orientation and alignment of the polymer chains during extrusion, followed by heat setting, contribute to the material's strength and stability.

Recyclability: The recyclable nature of PET also contributes to its resistance to environmental factors. PET can be processed and recycled into new products, which helps reduce waste and the need for new raw materials.

Longevity: The combination of these factors results in PET strapping tape maintaining its properties and performance over extended periods of time, even when exposed to varying weather conditions and environmental stressors.