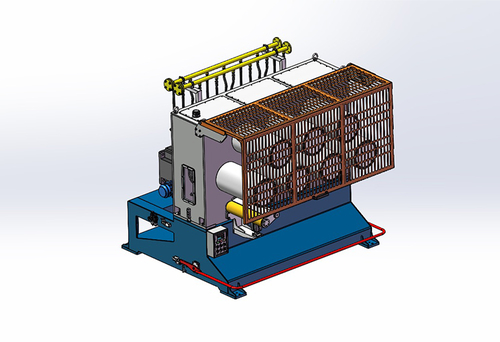

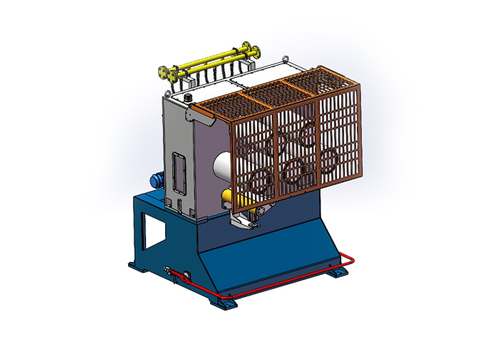

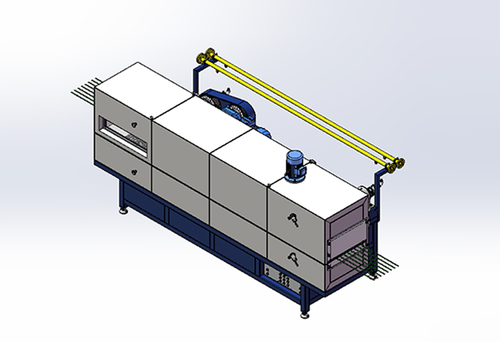

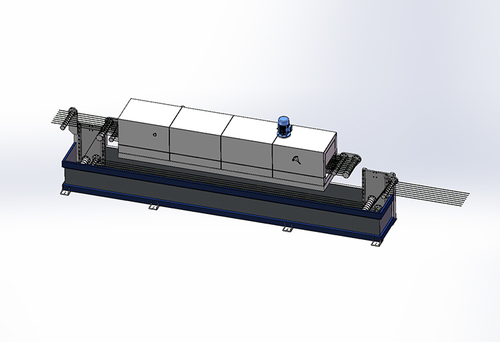

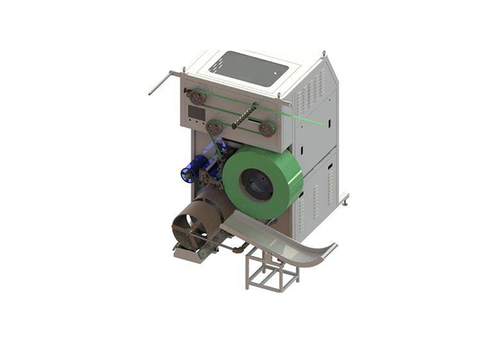

The packaged object is basically in the middle of the strapping machine. First, the right top body rises, the front end of the belt is pressed, and the belt is tightened and tied to the object. Then the left top body rises, pressing the appropriate position of the lower belt, and the heating sheet extends into the middle of the two belts. , the middle top knife rises, cuts off the strap, and finally sends the next strapping strap to the position to complete a working cycle.

Work process

The strap of the strapping machine is sent to the position → the strapping signal is received → the brake is released, the main motor starts (1) → the right top knife rises, and the right strap is held at the slide plate (2) → "T" guide plate moves back (3) → proximity switch Sensing the unwinding probe (4) → the main motor stops, the brake is engaged (5) → the unwinding motor of the strapping machine rotates, and the unwinding is 0.35 seconds (6) → the tape is tightened and tied to the object (7) → the main motor 2 The first start, the brake is pulled in (8) → the large pendulum rod pulls the belt for the second time, and the belt is tightened (9) → the left top body rises, and the lower belt is pressed (10) → the heating plate extends into the middle of the two belts (11) → middle The top knife rises and cuts the tape (12) → the middle top knife descends (13) → the middle top knife rises again, so that the two belts are firmly bonded (14) → the middle top knife descends, and the left and right top knives descend at the same time (15) → heating plate Reset (16) → Slide back (17) → "T" guide plate reset (18) → The proximity switch senses the tape feed probe (19) → The tape feed motor starts to drive the tape to feed the tape (20) → The large pendulum lever resets ( 21) → The strap is in place, and the head is placed on the "T" guide plate (22) → The proximity switch senses the double probe (23) → The main motor stops, the brake is pulled in (24) → The automatic strapping machine completes a working cycle.