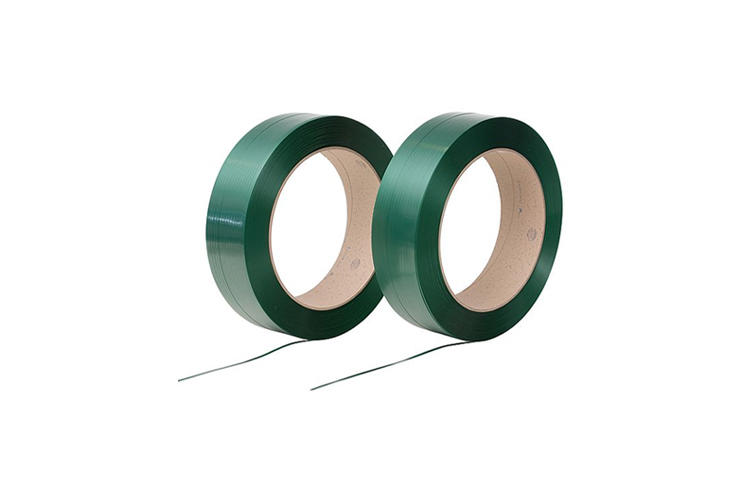

Material: PET strapping is made from Polyethylene Terephthalate, a thermoplastic polymer, while poly strapping is made from Polypropylene, another thermoplastic polymer. The difference in material composition leads to variations in their properties.

Strength: PET strapping is generally stronger and has a higher tensile strength compared to poly strapping. This means that PET strapping can withstand heavier loads and provides greater resistance to breakage or stretching.

Rigidity: PET strapping is stiffer and less flexible than poly strapping. It maintains its shape better and is less prone to elongation under tension. This rigidity makes PET strapping suitable for securing heavier loads that require higher tension levels.

Elongation: Poly strapping has higher elongation or stretchability compared to PET strapping. It can absorb shock and withstand impacts better, making it suitable for loads that may experience movement or vibration during transportation.

Resistance to UV and Weathering: PET strapping generally has better resistance to ultraviolet (UV) rays and weathering. It is less susceptible to degradation from exposure to sunlight, making it a preferred choice for outdoor applications or long-term storage.

Cost: PET Strapping Tape is generally more cost-effective compared to PET strapping. It is a more affordable option and is commonly used for lighter loads and general packaging needs.