An

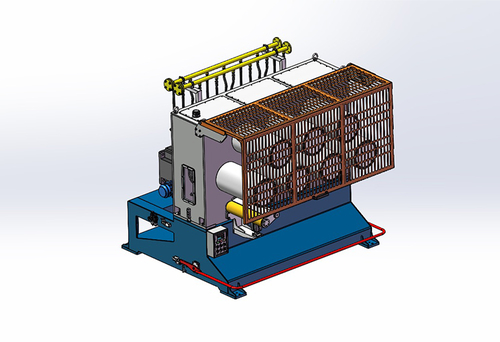

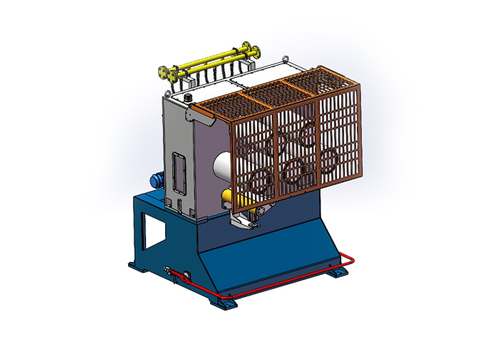

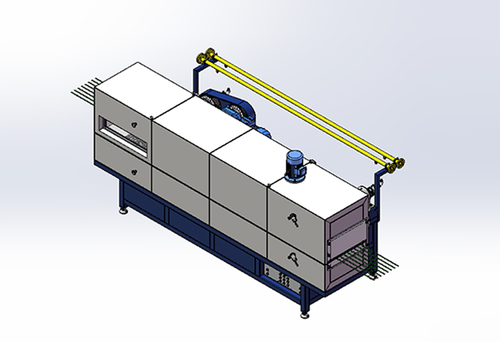

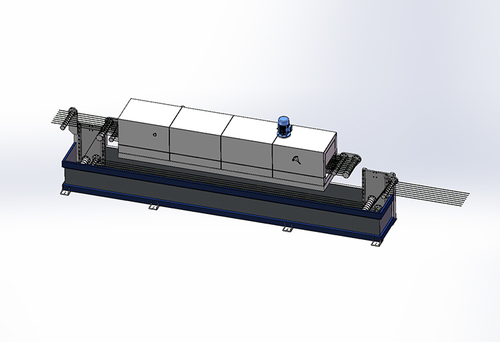

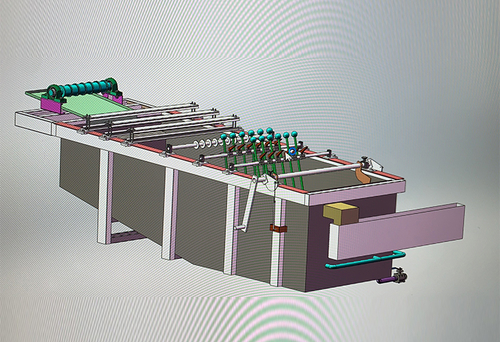

Automatic level-seal strapping machine with top presser is a high-quality, fully automated end-of-line system for tying and sealing polypropylene (PP) or polyester (PET) strap to bundle products for shipping. It's a powerful option that can be installed as an independent unit or at the end of multiple production lines.

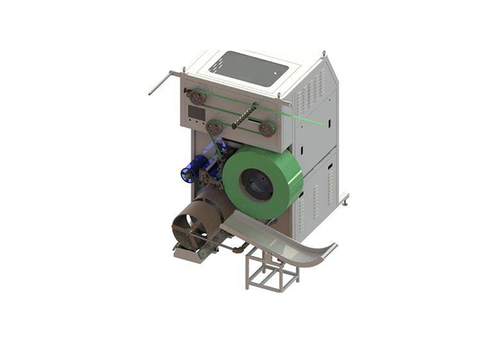

Auto Feed - An important feature for any high-volume strapping operation, Auto Feed makes loading and dispensing the coil of polypropylene (PP) or polyester strapping fast and simple. Simply load the strap on the dispenser, and then press the feed switch to have the coil thread through the machine.

Jam Free Auto Re-Feed - Eliminates the hassle of strap waste by retracting and re-feeding excess strap during the cycle. It also helps keep downtime to a minimum.Consistent Tension - The desired tension can be applied consistently to both compressible and non-compressible bundles with manual adjustment.

Efficient Design - Fewer moving parts results in greatly simplified design, making the machine very durable and easy to maintain. Energy Saving Operation - Motors run only during the strap cycle, providing the quietest working environment.

Sealing Head Strap Ejector - Removing unwanted strap from the sealing head eliminates down time caused by strap waste and unnecessary machine maintenance.

An automatic level-seal strapping machine with top presser is a type of strapping machine that is designed to automatically apply strapping tape to packages, boxes, or other items for secure transportation or storage.

The machine works by feeding the strapping tape through a series of rollers and guides, then applying it around the package using a sealing mechanism. The level-seal design provides a flat surface on the package for labeling or stacking.

The top presser feature of the machine applies pressure on the top of the package, ensuring that the strapping tape is tightly secured around the package. This feature is particularly useful for packages with uneven or irregular shapes.

The automatic level-seal strapping machine with top presser is commonly used in shipping and packaging industries, warehouses, and distribution centers where high volumes of packages need to be securely strapped for transit. The machine can increase productivity, reduce labor costs, and improve the overall efficiency of the packaging process.