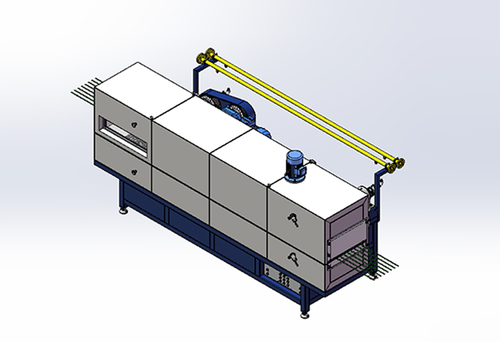

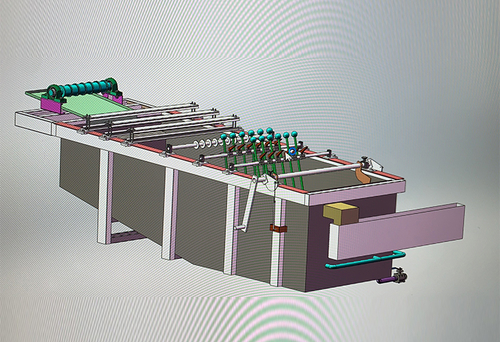

Plastic strapping is made by extruding strands and sheets of plastic. These are made from oriented polymeric material, which can increase plastic strength up to 10 times. The process also involves crystallizing and dehumidifying the plastic material. Therefore, it is essential that a strap extruder has a melt temperature control system that ensures high melt quality.

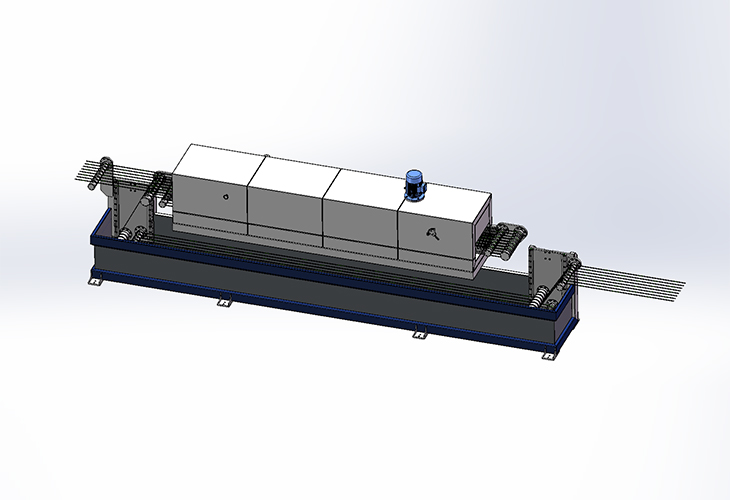

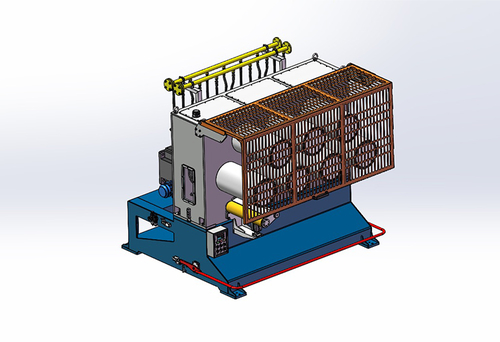

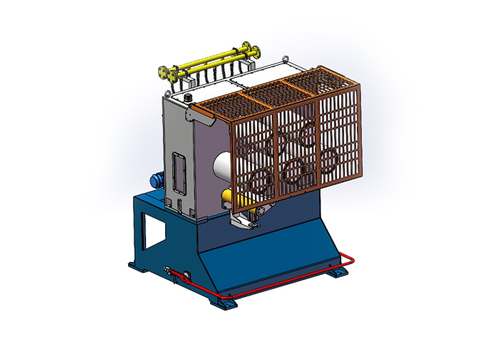

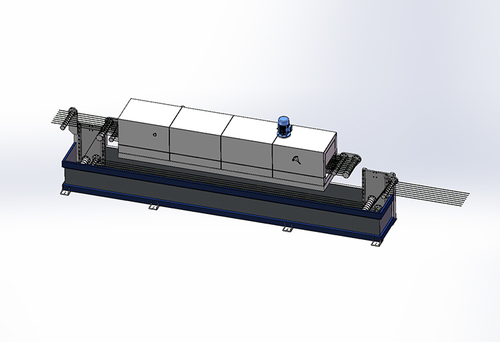

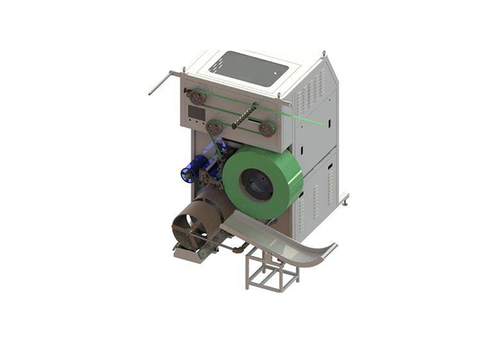

A PET Strapping Extruder is used for the production of PET Strap. PET Flakes are made from recycled PET Bottles. PET Bottles are crushed and hot-washed before being used to make PET Strap. A PET Strapping Extruder has a Dehumidifier and a crystallizer to heat up PET flakes and turn them into PET Strap. This machine also features a Jockey Extruder, which loads the PET Strap.

A strap extruder may include a rotary anvil that is rotatable relative to the strap. The anvil can define multiple bending profiles that are adjacent to each other about a rotational axis. The anvil also defines a follower portion that is positioned adjacent to the strap. The anvil can also include a first and second explosive charge disposed on opposite sides of the follower portion.