2. Before starting the machine, check the filling working mechanism of the packaging machine, observe the movement of the movable parts, and check whether the coordination of actions between the various mechanisms is coordinated.

3. Before starting the machine, you must first understand the amount of material in the intermediate warehouse, and start the machine when the material is fed to the specified material level.

4. Before starting the machine, check whether the air pressure meets the requirements (greater than 4Mpa), check whether the main components are in good condition, such as the cutter, packaging film, etc., usually check whether there are other personnel in the dangerous parts of the machine to ensure the safety after starting.

5. Before starting the machine, observe the surrounding environment and remove all obstacles.

6. When the packaging machine is just started, it should be idling for several weeks, observe the operation, and then start again

packaging.

7. Turn on the power, turn on the power switch, set and check the temperature on each thermostat, and install the packaging film.

8. First adjust the bag and check the coding effect, open the feeding quantity of the feeding system, when the material meets the requirements, open the bag first, and check the sealing effect and heat sealing quality of the seal at the same time.

9. In the production process, check the quality of the product at any time, such as whether the basic requirements of the product such as heat sealing line, fold, weight and quantity are qualified, and adjust it at any time if there is any problem.

10. The operator is not allowed to adjust the operating parameters of the machine at will. If adjustment is required, the main person in charge of the machine should apply to ensure that the operating parameters of the equipment are controlled during the production process, and to ensure normal production and product quality.

11. If there is a problem in the production process, it should be stopped immediately to deal with the problem. It is strictly forbidden to deal with the problem during the operation of the machine to prevent the occurrence of safety accidents.

12. The operator can only operate the touch screen gently by hand. It is strictly forbidden to press or tap the touch screen with fingertips or other hard objects. The touch screen will be compensated according to the price due to improper operation.

13. The operator packs the machine cleanliness at any time, and regularly adds lubricating oil to the main parts of the machine. Regular maintenance can prolong the service life of the machine.

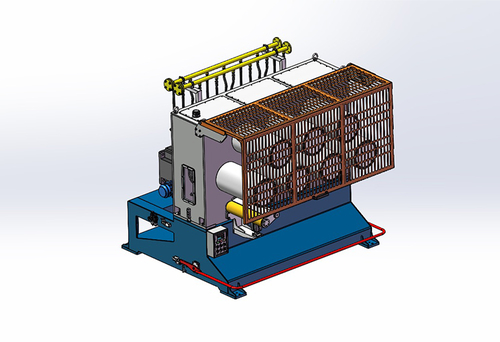

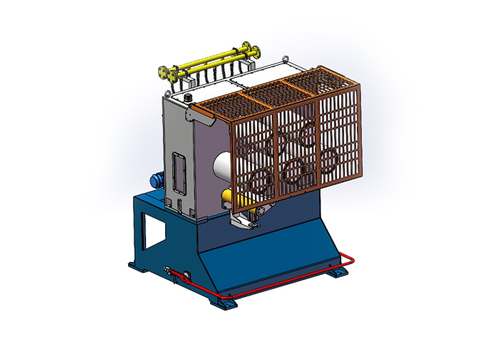

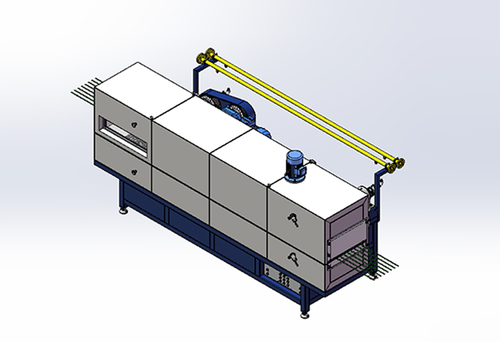

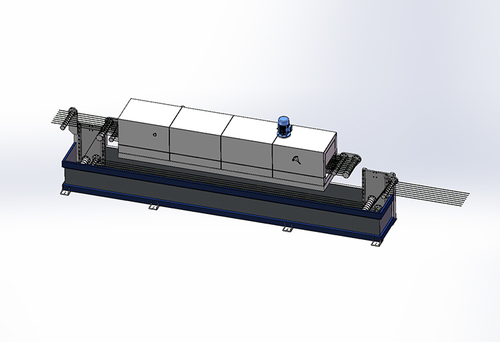

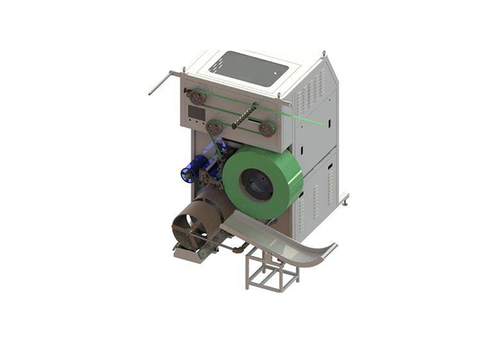

BST-1300 Automatic In-Line Cantilever Winding Machine