①Plastic strapping machine. It is a strapping machine for medium and small weight boxes. The plastic belts used are mainly polypropylene belts, but also nylon belts and polyester belts.

②Steel strapping machine. It uses steel strips as bundling materials. Due to the high strength of the steel strips, it is mainly used for heavy and large packing boxes.

Binding machines are classified by joint method

①Welding strapping machine. Because the plastic belt is easy to heat and melt, it is mostly suitable for plastic belt joints. According to different heating methods, it is divided into electric heating welding, ultrasonic welding, high frequency welding, pulse welding and so on.

② Buckle strapping machine. It adopts a special buckle joint, which clamps and embeds the joint of the strapping belt, and is mostly used for steel belts.

Classification by structural characteristics

①Basic strapping machine. It is a strapping machine suitable for various industries, and its table height is suitable for standing operation. It is mostly used for bundling and small packages, such as cartons, calcium plastic boxes, books and periodicals.

② Side-mounted strapping machine. The splice part of the strapping is done on the side of the package with a lower table. It is suitable for bundling large or polluting packages. If anti-rust treatment is added, aquatic products, pickled products, etc. can be bundled; if dust-proof measures are added, packages with more dust can be bundled.

③Pressure strapping machine. For soft and elastic products such as leather, paper products, knitted cotton fabrics, etc., in order to tie them tightly, they must be compressed before bundling. The pressurization method is divided into two types: pneumatic and hydraulic.

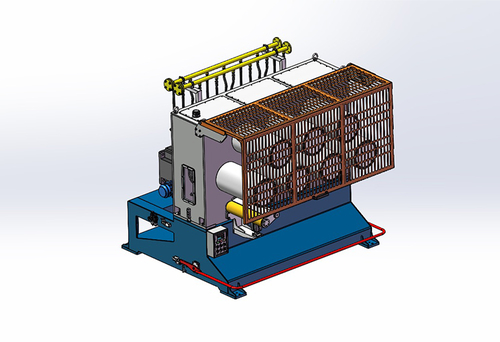

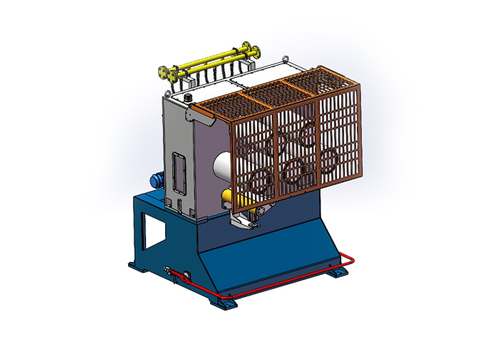

④Open and close the track strapping machine. Its belt track frame can be opened and closed in the horizontal or vertical direction, which is convenient for the placement of various cylindrical or annular packages, and then the track is closed and bundled.

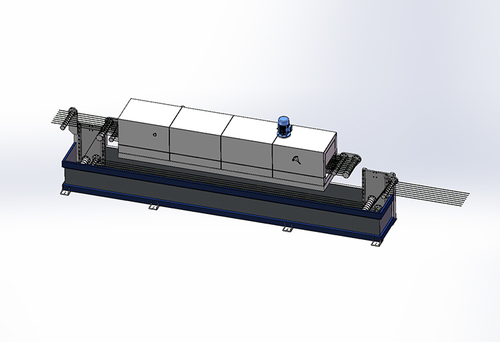

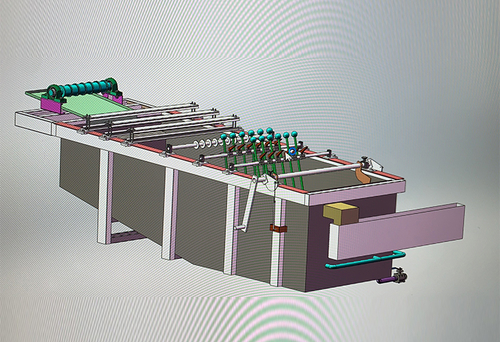

⑤ Horizontal track strapping machine. Its belt tracks are arranged horizontally, and the packages are bundled horizontally. It is suitable for transverse bundling of packages such as pallets.

⑥ Portable strapping machine. It is generally placed on the top surface of the package, and when the tape surrounds the package, the machine is used to tighten and lock the tape. It is operated manually, flexible and light.

Sort by degree of automation

① Manual strapping machine. Rely on manual operation to achieve bundling and locking, and use plastic straps for bundling. The structure is simple and light, and is suitable for bundling large-volume or small-batch packages.

②Semi-automatic strapping machine. The package is sent to the bundling station by the conveying device, and then the tape is manually wrapped around the package, and finally the tape is tightened and fixed. It has a low work surface and is very suitable for bundling large packages.

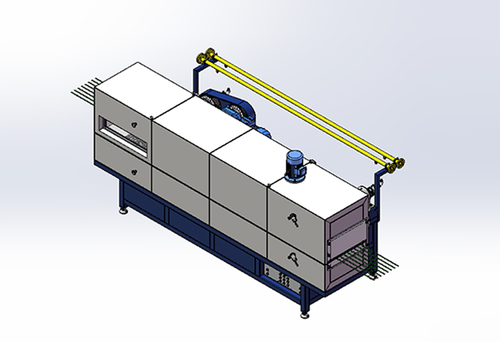

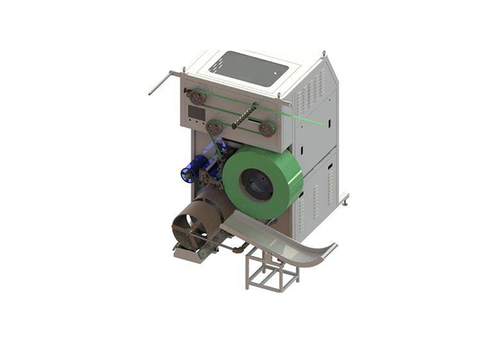

③ Automatic strapping machine. There is a belt track frame above the workbench. When the package enters the bundling station, the belt feeding and wrapping, pulling and tightening the belt, and fixing and cutting are automatically performed. The machine has a fixed track frame and is generally suitable for bundling packages with a single size and a large batch. When bundling, the movement and turning of the package must be done manually.

④Automatic strapping machine. The machine can automatically complete all the pre-determined bundling processes, including the movement and steering of packages, without human operation and assistance, and is suitable for bundling large quantities of packages.