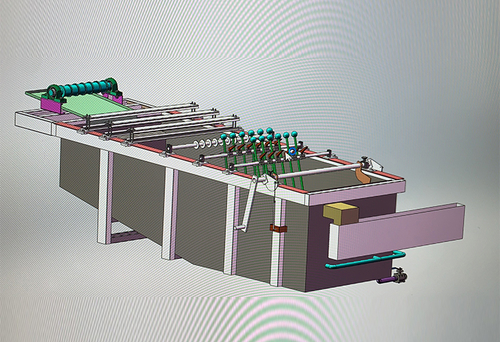

The working principle of the automatic baler is to complete the baling through tensioning, hot melting, tape cutting and gluing. The professional baler factory produces a wide range of applications, no matter the size of the package, it can be packaged without adjusting the machine. The automatic baler has a mechanical structure, and some imported baler accessories are used. The rear blade is stable and reliable, easy to adjust, and the price is reasonable.

The packaging object of the automatic packaging machine is basically in the middle of the packaging machine. First, the upper right body rises, presses the front end of the packing belt, and tightens the packing belt on the object. Then the upper left body rises, presses the lower belt in place, and the heating sheet extends into both sides. In the middle of the strapping belt, the middle top knife rises, cuts the strapping strap, and finally sends the next strapping strap to this position to complete a working cycle. A fully automatic baler is a machine that wraps a product or package with a tape, then pulls it taut and fuses the ends by thermal effect or uses materials such as hasps.

The function of the automatic baler is to make the plastic tape stick to the surface of the package to ensure that the package will not be scattered due to poor bundling during transportation and storage, and the bundling is neat and beautiful.

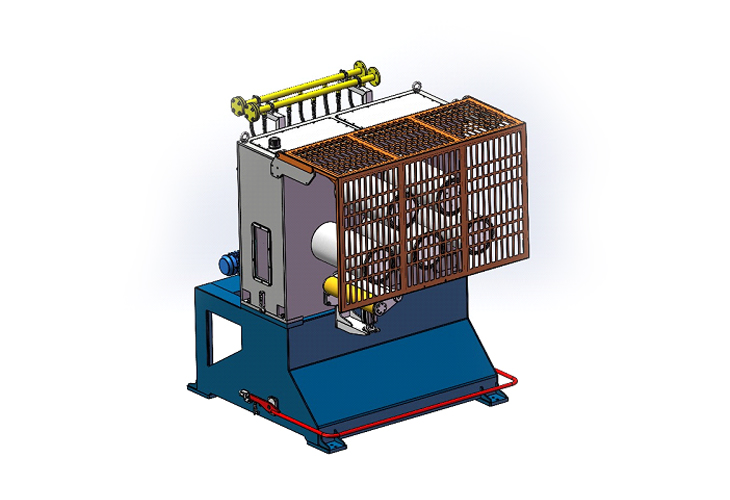

Automatic balers usually have two kinds of time relays, one is used to control the time of packing and baling, generally 3S or 60S; the other is used to control the output time, generally 5S or 6S. There are three common types, one is the JS14A-y external type, the body is installed on the horizontal plate, and the adjustment knob is installed on the operation panel; the other is the turntable type, the body is installed on the operation panel, and there is a Large turntable; in addition, there is a digital display, which is mounted on the operation panel.

Automatic balers usually use two transformers, the smaller one is the control transformer, the input is 220V, and the output is 24V, which provides the working power of the control loop. The larger one is the hot melt transformer, the general input is 380V (single-phase power supply packaging machines use 220V a lot), the output is generally 1V, divided into five levels, the first level of hot melt current is small, and the fifth level of hot melt current is larger.

The automatic baler has two AC contactors, one controls the work of the clutch, and the other controls the work of the hot melt transformer. The general working voltage is 220V and the working current is 10A.

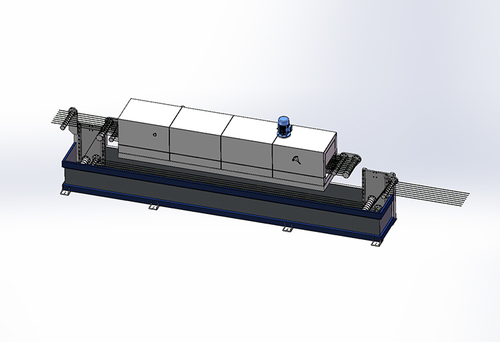

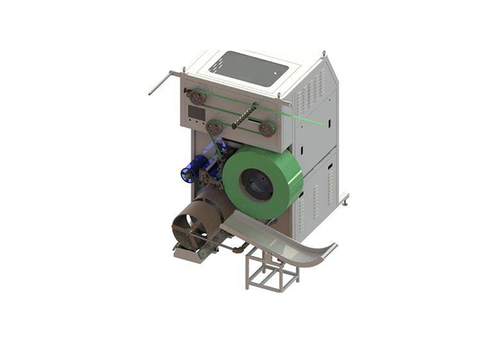

Draw stand with 5 rollers