The automatic packing machine is suitable for the automatic packing and bundling of various sizes and goods such as carton packing, paper packing, etc. in China's food, medicine, hardware and other industries. The fully automatic packing machine does not need manual tape insertion, with high work efficiency and low labor intensity; outstanding packing strength, fewer failures, and convenient maintenance; the packer parts are finely processed by computer numerical control machine tools; the packing technology has soft movements, good durability, and packing The service function is continuously improved; after the packaging is completed, the motor should be stopped immediately to save electricity and make it practical.

1. The automatic packing machine is classified according to the bundling material:

1. Plastic tape packing machine. The utility model relates to a binding machine for medium and small weight packaging boxes. Plastic belts are mainly polypropylene belts, but also nylon belts and polyester belts.

2. Steel strapping machine. It uses steel strips as bundling material, and is mainly used for heavy and large packing boxes because of its high strength.

3. Portable pneumatic baler. This pneumatic baler system is generally applicable to China's metallurgy, steel, building materials, etc., and is suitable for various PET plastic steel belts. Tightening, bonding, and cutting can be completed at one time in enterprises, and the operation method is simple.

2. Automatic packing machine are classified according to structural characteristics:

1. Basic packaging machine. It is a baler suitable for various industries, and its table height is suitable for standing operation. Mainly used for bundling small and medium-sized packages such as cartons, calcium-plastic boxes, books and periodicals.

2. Side-mounted packer Side-mounted packer. The splice part of the strapping is done on the side of the pack with a lower work surface. It is suitable for large or polluted packaging, such as adding anti-rust treatment, it can bundle aquatic products, pickled products, etc. If dust-proof measures are added, more dust-proof packaging can be bundled.

3. Pressurized balers. For soft and elastic material products such as Chinese leather, paper products, knitted cotton fabrics, etc., in order to tie them tightly, it is necessary to press and fix them first and then tie them. There are two types of pressure treatment methods: pneumatic and hydraulic systems.

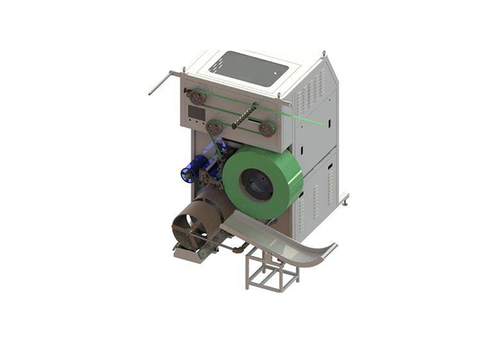

4. Open and close track balers. Its belt track system frame technology can be opened and closed in the horizontal or vertical direction of life, which is convenient for the placement of various cylindrical or annular packages, and then the China track circuit is closed and bundled.

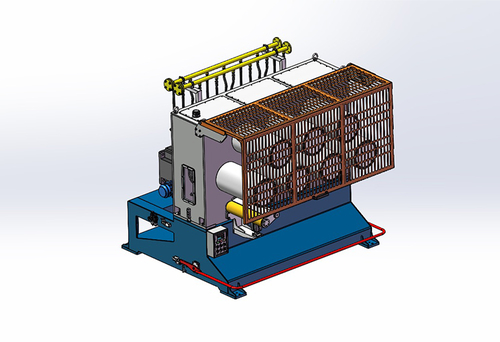

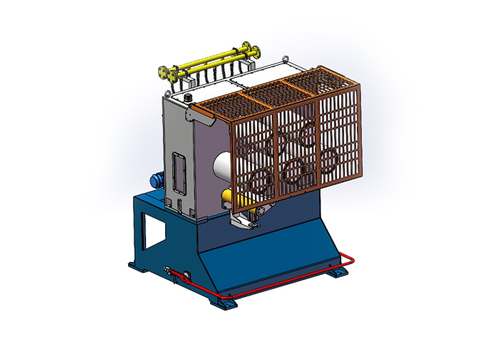

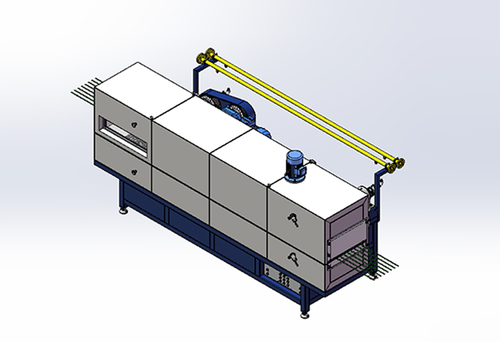

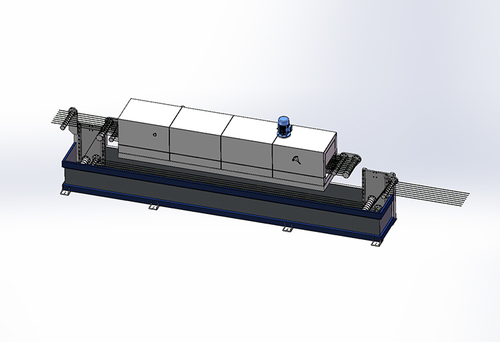

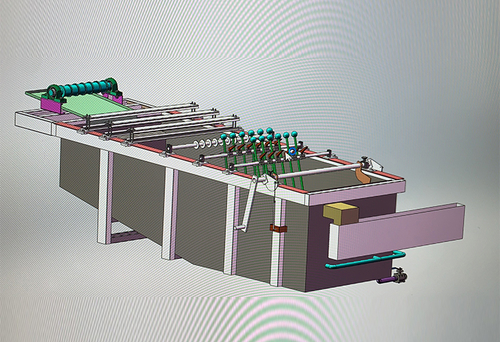

5. Horizontal orbital packing machine. The belt rails are arranged horizontally and the packages are bundled horizontally. It is suitable for horizontal bundling of pallets and other packaging.

The principle and characteristics of the automatic packing machine: adopting the technology of the brand packing machine, the machine is now designed with double-loop control, which is more stable and reliable than the previous single-loop control. The double-loop control reduces the internal load of the machine board. The loops in between run more smoothly. As a packer manufacturer, we have better performance, more reliable quality, easier testing and commissioning, and photoelectric control for easy clutch use.

Horizontal Baler DBA-600L