Wrapping machines are a great way to improve your packaging process. They can reduce the time it takes to wrap a pallet and save money on materials by pre-stretching your film.

They also ensure a consistent and high-quality wrap, which is impossible to produce by hand, and they can stabilize loads that may shift or fall during shipping. They’re ideal for storing and transporting all types of products, from delicate to heavy.

These machines can be purchased individually or as part of a set of robotic packaging equipment. It’s important to find a supplier that understands your needs and can customize a stretch wrapping solution for your business.

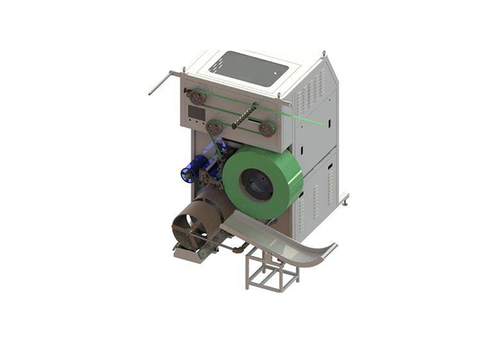

The best automatic stretch wrappers maximize throughput and efficiency. You don’t need an operator to change the roll of film and they can keep up with production rates of all sizes.

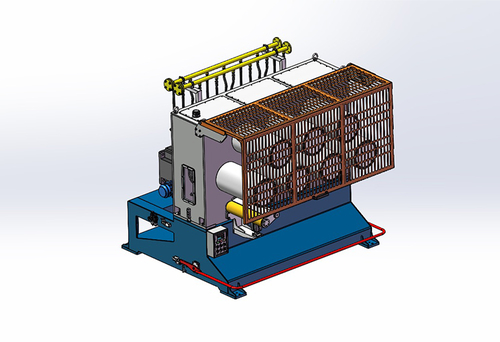

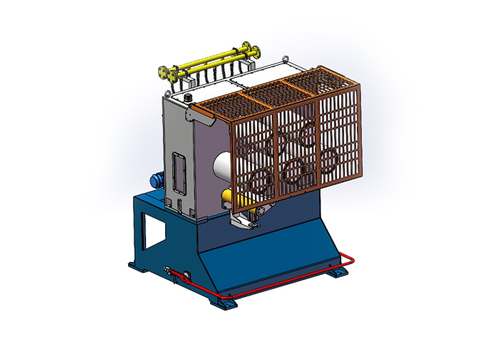

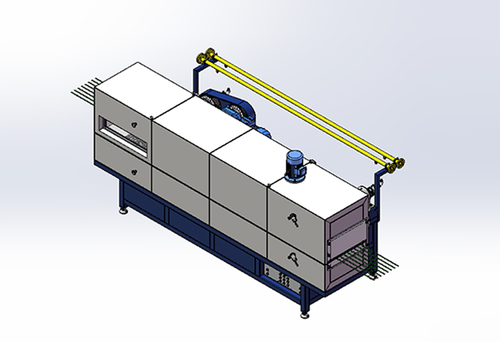

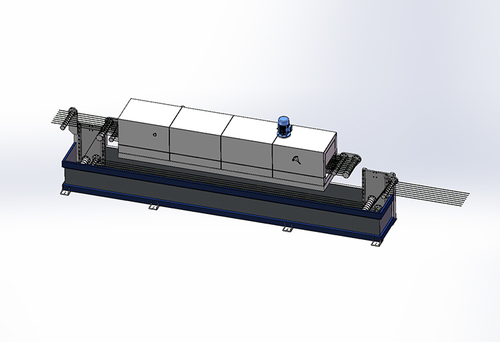

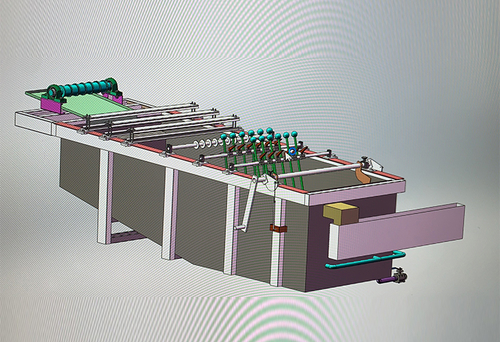

You can choose from a wide variety of models and styles, including simple automation, automatic rotary arm, automated straddle, portable, and conveyorized. The type you pick depends on your product and production requirements, as well as your budget.

A stretch wrap machine can help your warehouse increase productivity by up to 25 percent, especially if you’re a large or small facility. It’s easy to move and can be used anywhere throughout your facilities, so it can improve efficiency and help you manage a variety of shifts and seasonality.

Wrapping machines can significantly improve your packaging process in a number of ways. Here are some of the benefits you can expect to see:

Increased Efficiency: Wrapping machines can significantly increase the speed at which you can package your products. This can result in a much more efficient process that saves you time and money in the long run.

Consistency: Wrapping machines ensure that each product is wrapped consistently, which can improve the overall appearance and quality of your products.

Reduced Labor Costs: By automating the wrapping process, you can reduce the need for manual labor and save on labor costs.

Improved Safety: Wrapping machines can help reduce the risk of injury that comes with manual wrapping. This is because the machine takes care of the wrapping process, so workers don't have to do it manually.

Reduced Material Costs: Wrapping machines can also help reduce the amount of wrapping material that is used, which can save on material costs.

Customizable Wrapping: Many wrapping machines offer the ability to customize the wrapping process based on the product being packaged. This can be especially useful for products that require special care during the packaging process.

Overall, wrapping machines can be a valuable investment for businesses that package products on a regular basis. They can save time, reduce costs, and improve the quality of your products, making them a worthwhile investment for many businesses.