1. Before working every day, the conveyor belt of the machine must be wiped with air pressure to keep it clean.

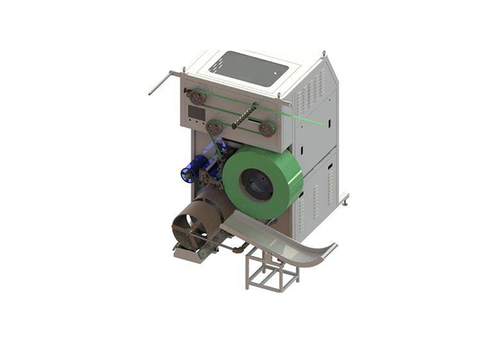

2. Maintenance of residual recycling axles:

(1) Maintenance once a month.

(2) Remove the fixing nut of the collection wheel, and take out the spring and collection wheel.

(3) Apply butter on the contact surface between the shaft and the collection wheel to keep the collection wheel running smoothly.

3. When the residue of the shrink film is found at the edge of the sealing and cutting knife, please use a cork board to gently remove the residue on the surface. It is forbidden to use metal wiping. Metal friction will destroy the protective film on the knife and reduce the function of the sealing knife.

4. Bearing and bearing seat maintenance: about once every three months, the outer surface of the machine is equipped with the bearing and the bearing seat, and hydraulic oil droplets are required to maintain lubrication in the contact gap between the bearing and the spindle to ensure the machine surface. clean.

5. Chain and sprocket maintenance: maintenance about every three months, first remove the protective cover of the transmission part, apply butter to the contact gap between the chain and the sprocket, and then replace the protective cover after maintenance.

6. Adjust the tightness of the belt: After the belt runs for a period of time, the belt will loosen. If the belt cannot be driven tightly, the tightness of the belt needs to be adjusted.

7. Check whether the fixing screw of the cutter is locked. If it is loose, lock it. (1 time per month)

8. Check the Teflon tape on the sealing silicone strip. If it is damaged, it needs to be updated.

9. If the Teflon on the cutting knife has fallen off and the film is easy to stick to the cutting knife, the cutting knife must be treated with Teflon again or a new sealing knife must be replaced.

10. Electric heating tube replacement: When the electric heating tube cannot be heated, the electric heating tube must be replaced.

(1) Before replacing the electric heating tube, you must first confirm whether the voltage and wattage of the electric heating tube are in compliance, and then turn off the power supply and wait for the residual heat of the electric heating tube to be eliminated.

(2) Remove the wires of the electric heating tube located in the wiring box.

(3) Loosen the fixing screws of the electric heating tube, take out the electric heating tube, and put the newly purchased electric heating tube in.

(4) Make sure that all the screws are fixed and locked, and then lock the wiring box after connecting all the lines.

11. Keep the lifting screw well lubricated: maintain it about once a month, first remove the outer baffle and apply butter to the contact gap between the T-shaped screw and the T-shaped nut, and then turn the adjustment handle lifting device to adjust up and down, so that the lubricating oil can be fully lubricated , you can install the outer baffle back after maintenance.

12. Replacement of heat-resistant rubber or heat-resistant tape:

(1) Turn off the power and remove the heat-resistant tape after the residual temperature of the electric heating tube is eliminated.

(2) Take out the heat-resistant rubber, replace the newly purchased heat-resistant rubber, and install it with the concave surface of the knife seat to ensure that the surface is completely flat, and remove the long and redundant parts.

(3) Then put the heat-resistant tape on it. Note that the tape must be flat and not wrinkled.

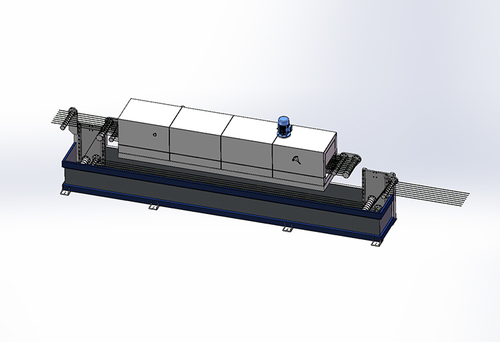

Quench Tank