For irregularly shaped or oversized packages, using a standard strapping machine may pose challenges. These packages may not fit properly into the strapping machine, making it difficult to apply the straps effectively or securely. Additionally, irregular shapes may not allow for consistent tensioning and sealing of the straps.

To handle irregularly shaped or oversized packages, there are a few options to consider:

Manual strapping: For occasional or one-off packages, manual strapping using handheld tools can be employed. This method allows for greater flexibility in handling various package shapes and sizes, but it is more labor-intensive.

Specialty strapping machines: Some manufacturers offer strapping machines specifically designed to handle irregularly shaped or oversized packages. These machines may have adjustable components or unique strapping methods to accommodate different package types.

Custom solutions: In some cases, specialized packaging solutions may be necessary. This could involve custom-designed strapping systems or other types of securing methods, such as stretch wrapping or shrink wrapping.

It's essential to assess your packaging needs and consult with a packaging equipment provider to determine the best solution for handling irregularly shaped or oversized packages. They can help you find the most suitable equipment or custom solution to ensure secure packaging and shipping of your products.

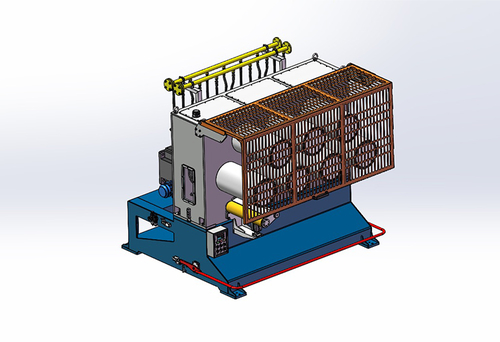

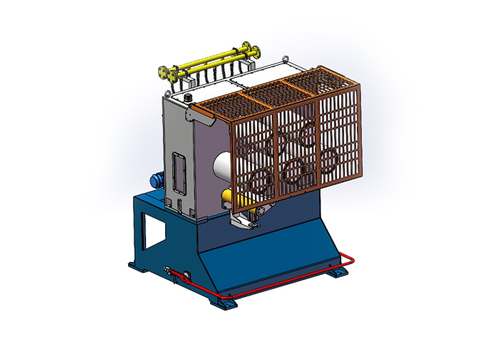

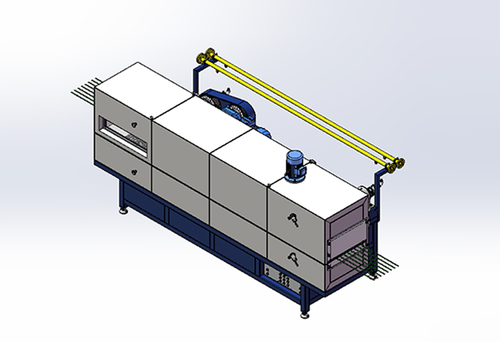

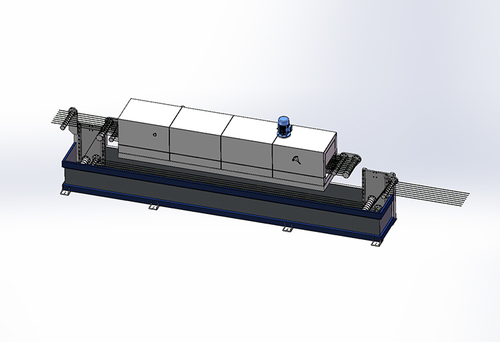

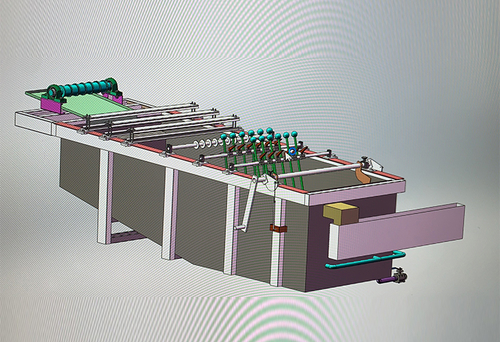

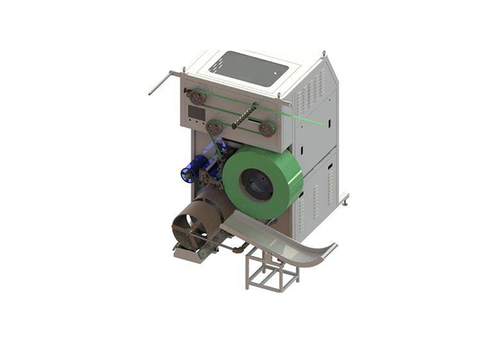

Automatic side-seal strapping machine with flap frame